Chipless Tube Cutting & Straightening Machine

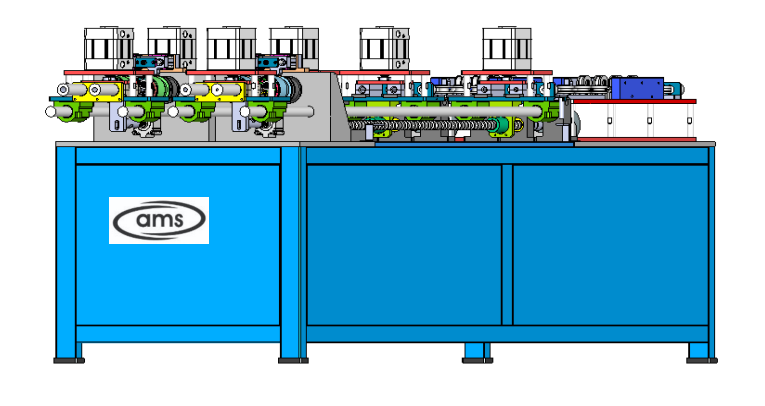

This machine is specially designed for straightening coil copper tubes, detecting length and chipless cutting automatically.

This machine is used for air conditioner, refrigerator or heat exchanger workshops, straightening coil copper tubes and burrless cutting into certain length.This machine adopts pull-apart cutting technology which is the most advanced cut-off method in the world, which eliminates or minimizes tube ID reduction that could occur and brings burr-less cutting result as well

Main features :

- Servo feeding, stable and high repositioning precision

- One time cutting four pieces, high efficiency

- Adopting stretch-breaking cutting method, chipless and less mouth shrinking rate

- PLC control, HMI operation, high automation– auto feed, cut and unload, auto alarm.

| 1 | Equipment name | Automatic copper tube straitening & burless cutting machine for refrigeration pipe |

| 2 | Spec & model | CTSCM4 |

| 3 | Purpose | This machine is used to copper tube cutting |

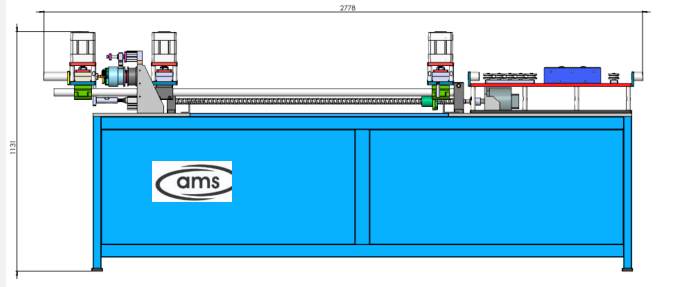

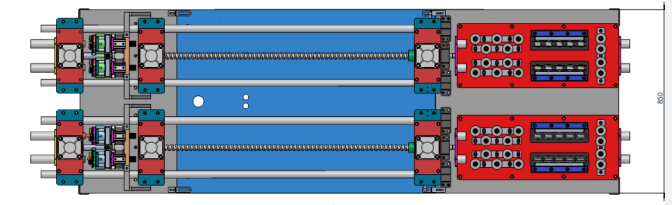

Installation’s layout drawing ( attached drawing 1)

| Main Components | ||

| No | Item | Brand |

| 1 | PLC | Delta |

| 2 | HMI | Delta |

| 3 | Servo motor | Delta |

| 4 | SMPS | Omron |

| 5 | MCB | Schneider |

| 6 | Contactor | Schneider |

| 7 | Realy card | Omron |

| 8 | Sensor | Kaltronic |

| 9 | Induction motor | Havells |

| 10 | Rail guide | Hiwin |

| 11 | Switch & buttons | Vertex |

| Free spare parts' quantity and unit price | |||

| No | Item | quantity | Unit |

| 1 | Contactor | 7 | PCS |

| 2 | switch & buttons | 5 | PCS |

| 3 | OLR | 6 | PCS |

| 4 | MCB | 2 | PCS |

| 5 | Relay | 2 | PCS |

| 6 | SMPS | 1 | set |

| 7 | Sensor | 6 | set |

| Machine's color and safety | ||

| No | ||

| 1 | Item | Color |

| 2 | Host body | AMS Standard Color |

| 3 | Host body of main Electric cabinet | AMS Standard Color |

| 4 | Electric cabinet’s door | AMS Standard Color |

| 5 | Guard's part | AMS Standard Color |

| 6 | High speed moving parts | AMS Standard Color |